A rivet is probably a term that most everyone has heard, but not everyone has seen in action. A simple way to think of a rivet is as a permanent bolt. You put it through a hole like a bolt, and once tightened (squeezed or hammered) it holds in place with heads on both sides like a bolt, but it’s permanently deformed into place and can’t be removed without destroying it (i.e. drilling it out.)

There are 2 types of rivets used on my aircraft, solid rivets and pop (or “blind”) rivets. To learn more about solid rivets, see my post HERE.

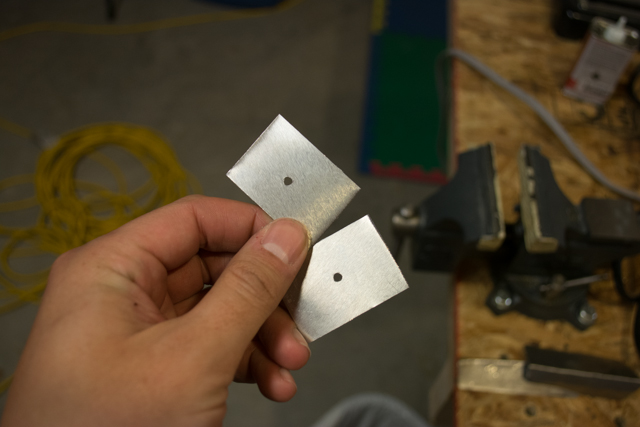

This is a cherry CCP-42 pop rivet.

This rivet is designed to be placed in a 1/8″ hole, which I have drilled in these pieces of scrap metal.

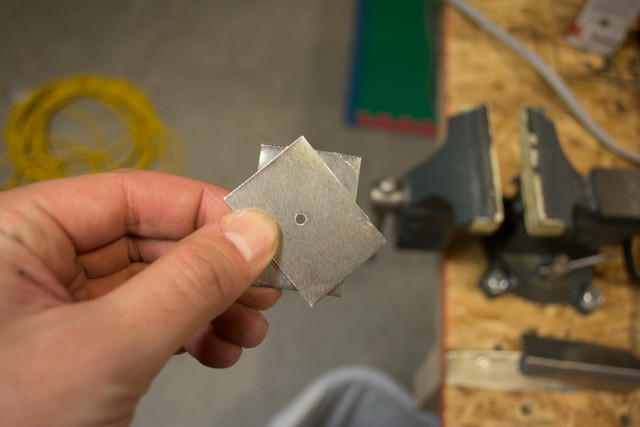

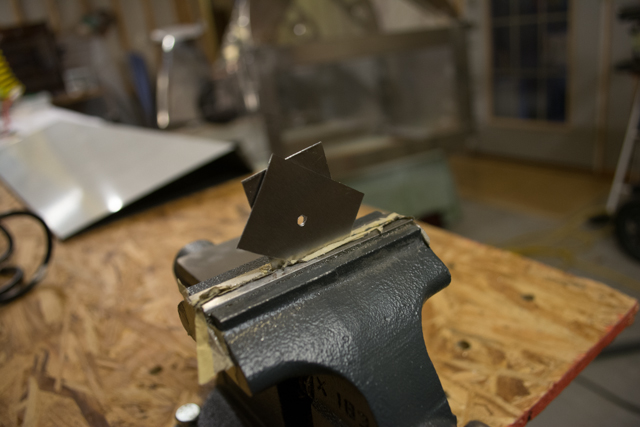

I’ll place the pieces together in a vise to free my hands up for riveting, and insert the rivet through the hole with my fingers.

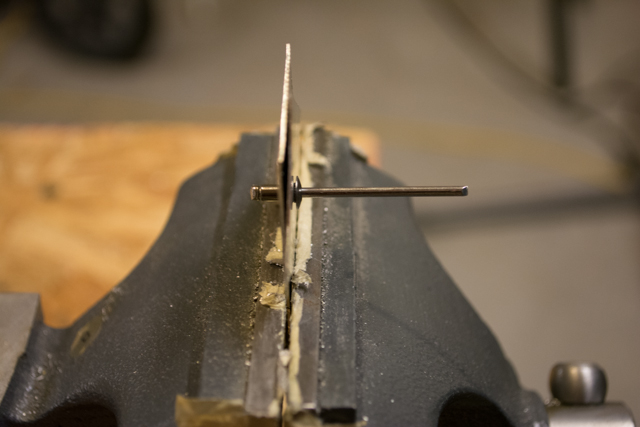

The rivet itself is the short shank that passes through the hole. That longer pin is actually used to pull on the rivet, compressing it on the far end and eventually breaking off once the rivet is set. The rivet gun has jaws inside of it that will grab that pin and slowly pull very hard on it, while I maintain pressure on the head of the rivet, like so.

The rivet is now compressed (or “set”) and holds the 2 pieces of metal tightly together. The pin has broken off as designed.

When the pin breaks off there is a distinctive “POP” or snap sound, hence the name of this type of rivet. When I get to the assembly of the main wing spar I’ll be using solid rivets, and will describe how they work (they are simpler in concept, but more difficult to install.)

One Response to What is a rivet? (Pop rivets)