Total build time: 208 hours.

With several large skins ready for riveting, I needed to get some polishing out of the way before proceeding with construction. I’ve decided that I will not be painting my aircraft (other than the small fiberglass parts, wing tips etc.) There are several reasons for this including looks, weight savings, and cost savings.

Polishing is easier on a flat surface than on the airplane as a whole. Also I’ve noticed in other polished aircraft that it’s difficult to remove the milling haze around the rivet heads (sort of a hazy shadow) if the skin has already been riveted before the first passes of polish are applied. This is why I’m polishing before rivets.

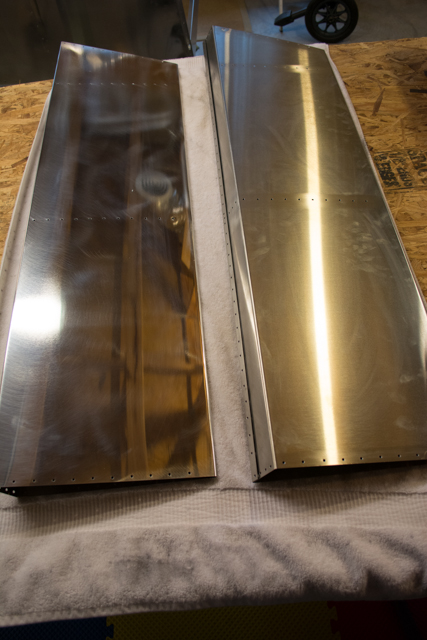

The stabilators are up first. Before:

After:

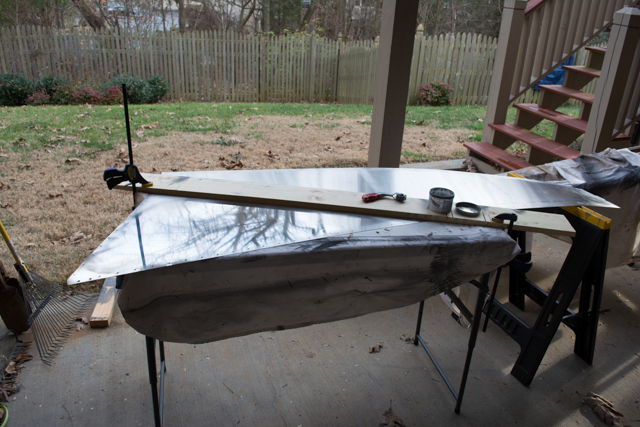

Then come the turtledeck skins.

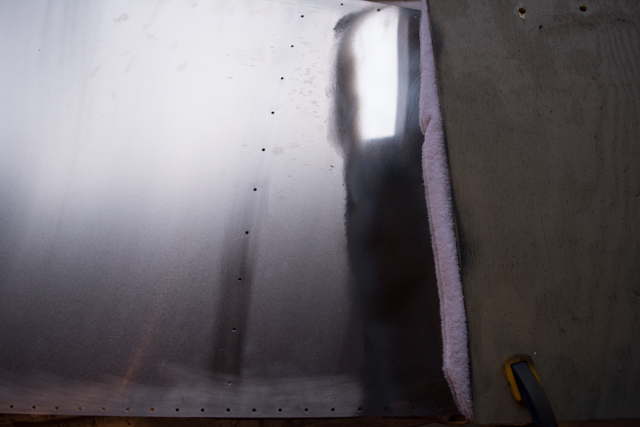

Here you can really see the contrast between polished and unpolished aluminum.

7 hours later, shiny metal!

For other builders, this was 3-4 passes of Nuvite F9. I’m not going to C grade before aircraft completion. There are plenty of swirls and holograms, but the “compounding” phase is complete and I should be able to get a great final result in the end without hazy rivet shadows.