Total build time: 315 hours.

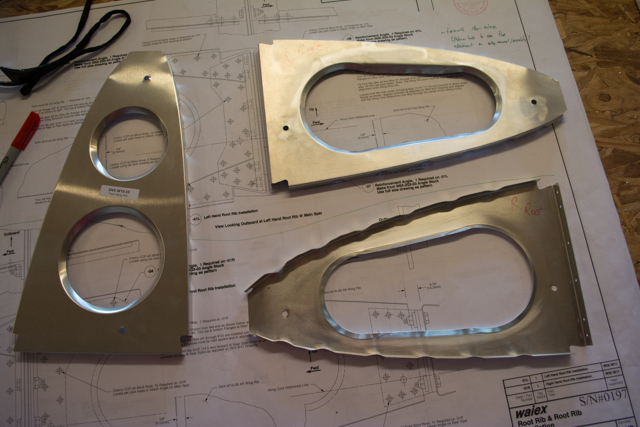

For the forward root ribs I made a popular modification that increases access to the flap drive tubes during wing installation and removal. A typical rib is on the left. I connected the 2 holes to create 1 large hole.

This is as far as I went with the root ribs for now. Even though the plan sequence calls for the root ribs to be installed first, most every builder I’ve referenced says to install them as the last rib in the substructure since they need to be custom cut and fit.

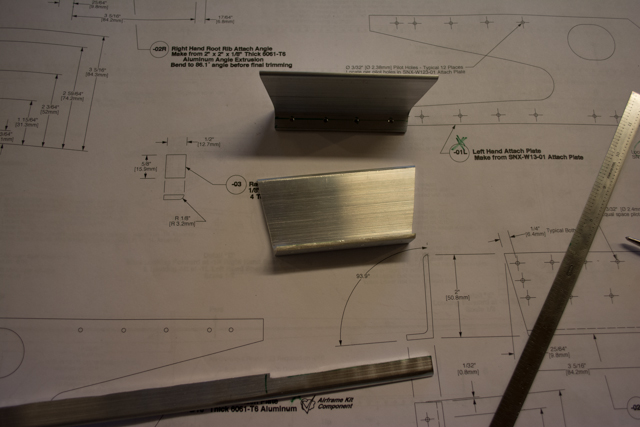

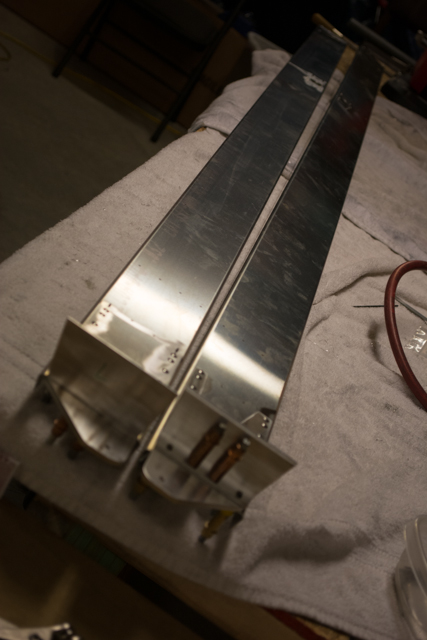

The final assembly I needed to make before I could begin assembling the wing substructure is the rear spar. This involved fabricating and bending a few more angle components for the root rib attachments.

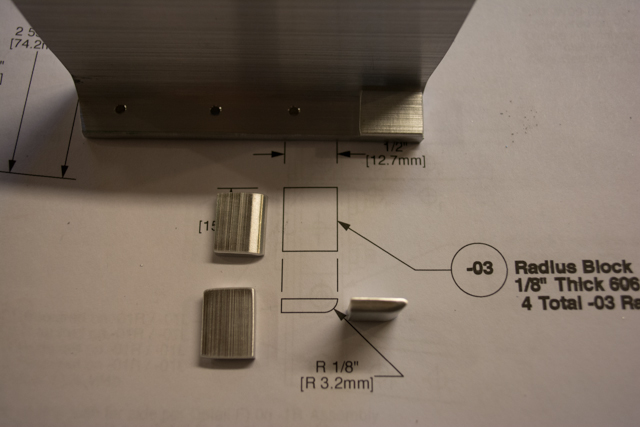

There are also 4 small “radius block” spacers to be made. In the picture above (at the bottom left) is a piece of scrap that was ripped from an angle earlier in the project. Since the radius block needed a 1/8″ radius on one edge, the piece of scrap already had a nice curve on it. I ripped this scrap piece further down on one end to get the desired width, then deburred and finished it before slicing it into the 4 spacers.

My version of the plans show the rear spar as 2 channels that need to be joined by a strap, but provided in the kit was the entire channel. This eliminated some work (and some weight!) From here is was mostly just cleco, drilling, deburring and riveting.

I had to remove some material from the doubler at the aileron push-rod hole to fit flat against the spar channel. Everything else was pretty straightforward, though the stacking and orientation of parts at the root end of each spar is different for left and right (as seen in the pic above.)