Total build time: 546 hours.

My wings, aft fuselage, and empennage are complete. Work now turns to the forward fuselage, which ties everything together. The wings, aft fuselage, engine and pilot are all connected through the forward fuselage. This means that the forward fuselage is both complex and very strong. Strength comes largely from a multitude of angle components, all of which I will make from stock aluminum angle. More than half of the angle components in the aircraft are located in the forward fuselage, so a lot of fabrication must happen before anything can be assembled.

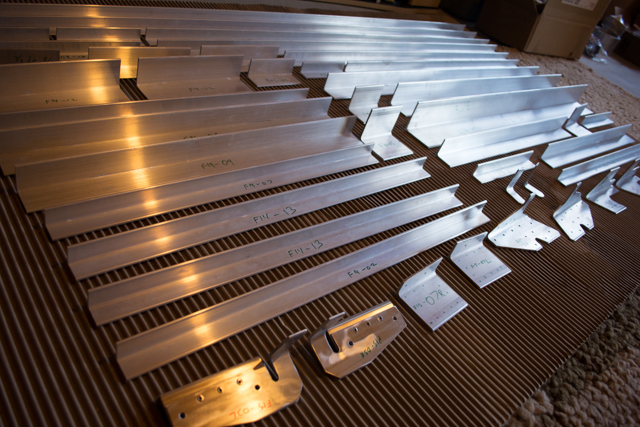

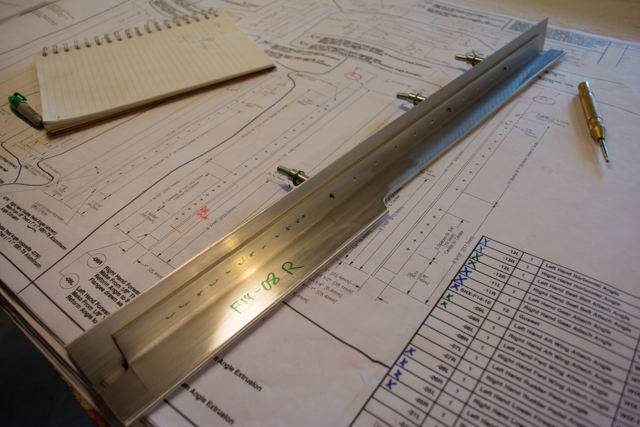

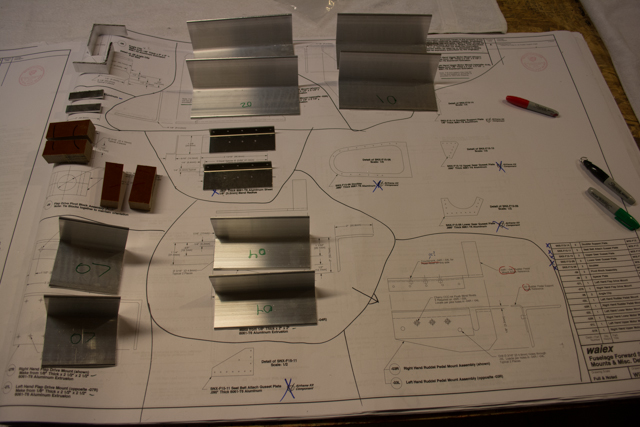

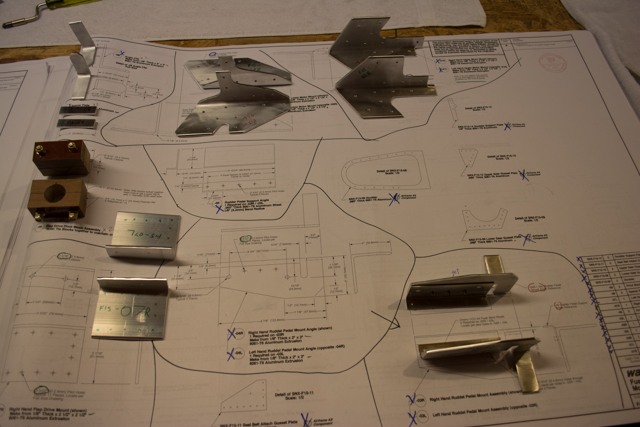

To begin, I cut lengths of angle from longer pieces. These pictures represent the majority of angle parts that I’ll be making for the forward fuselage:

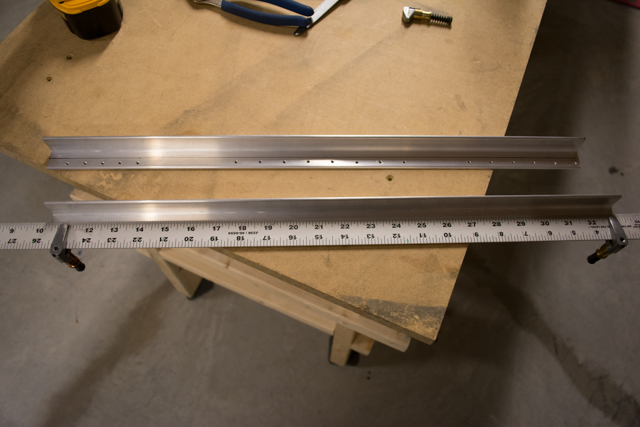

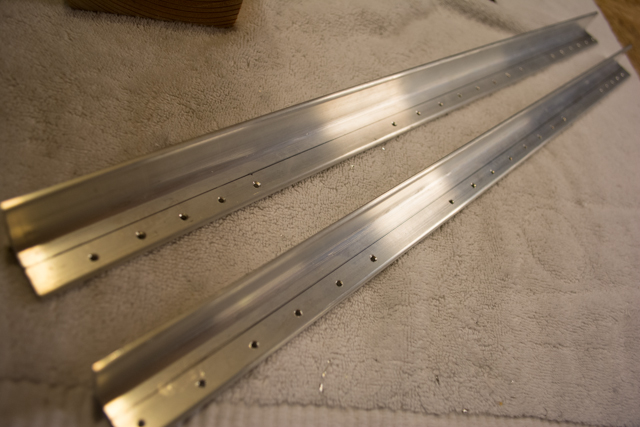

Many of the parts need holes drilled in them:

Most of the time I will drill the holes in the right-side version of the part, then clamp and drill those same holes into the left-side part.

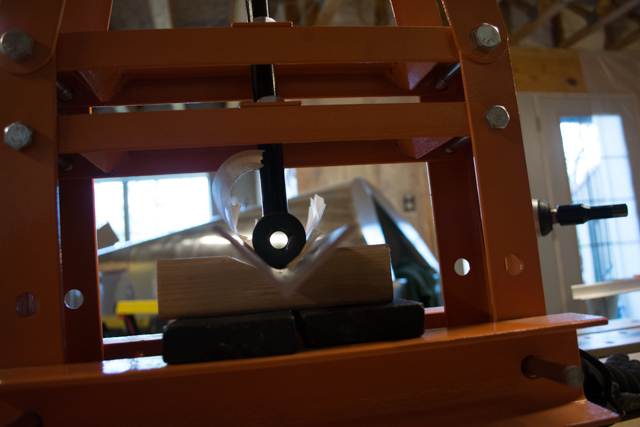

Other parts need to be bent to certain angles:

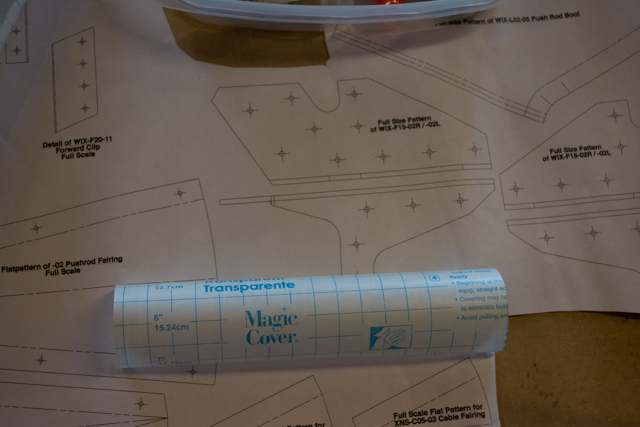

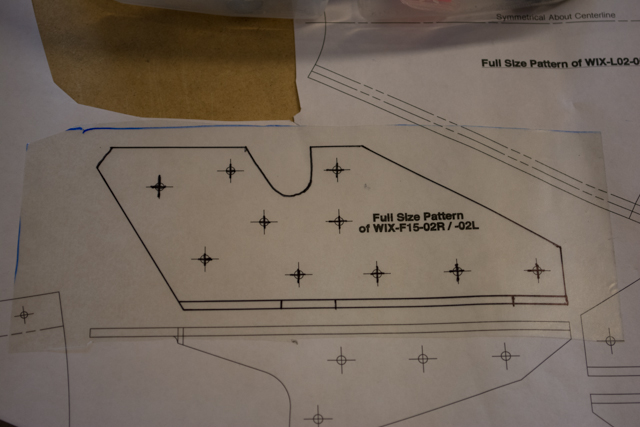

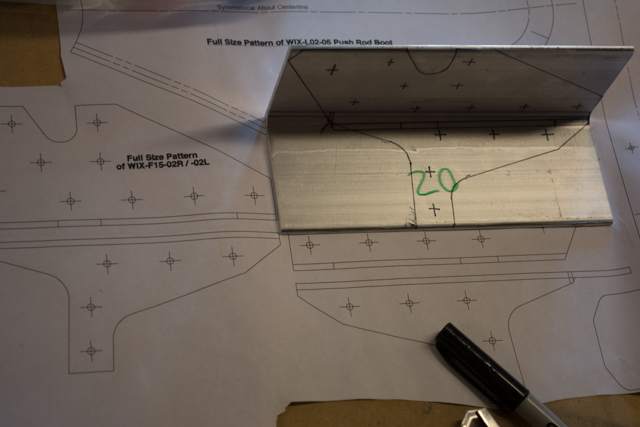

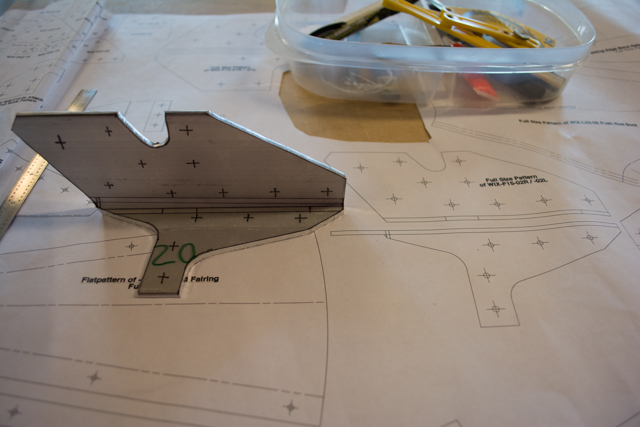

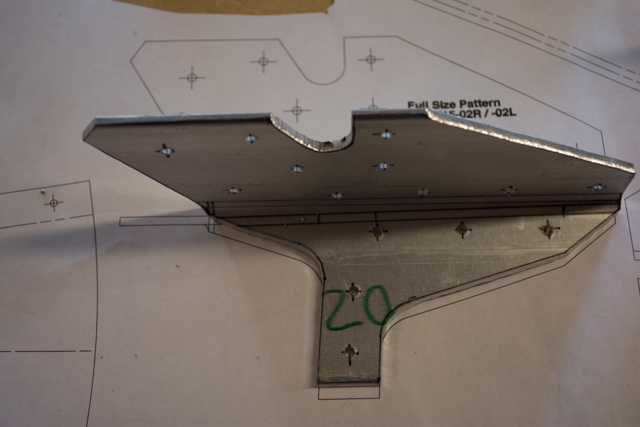

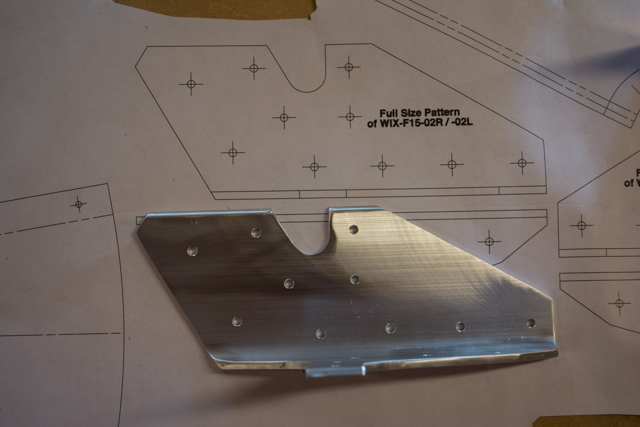

For some of the really complex shapes, the plans include full-sized templates to help in cutting the part. I was able to transpose these templates with a high degree of accuracy using transparent sticky plastic called Magic Cover from the craft store.

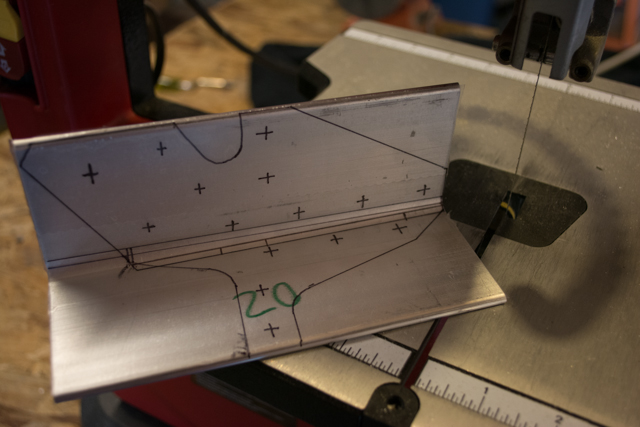

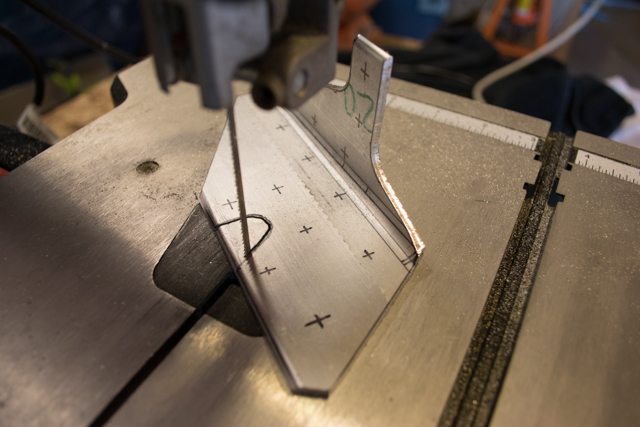

I then used the band saw to make the cuts, and marked and drilled the hole locations.

But all the work isn’t with aluminum! Blocks made from phenolic material are also made. They will act as bearing surfaces for flap and rudder controls.

Here is a full page of parts going from stock angle to shiny finished parts:

These parts have to me made to an extra high degree of accuracy, because there are no laser-cut holes to assist on the parts onto which they attach, which is unlike most other parts of the aircraft so far. I took my time with each an every part to achieve a high quality and accurate finish.

I completed all of the parts needed to move on to the next assembly stage, which is the fuselage side panels. There are still about a dozen angle parts left to fabricate for the forward fuselage, and I will make them when I reach the appropriate stages in the plans.

Parts are looking good!

Thanks Bryan! Here’s to hoping my parts at least bear a passing resemblance to the machined parts in your kit!

They look good in the pics. The machined angle parts are awesome- nice edge finishing right out of the box.