Total Build Time: 681 Hours

Installation of the main landing gear began with inserting the titanium gear legs into the engine mount.

I then drilled through the titanium gear legs (no easy feat indeed!) to position the rods inside the engine mount, and set the camber of the main landing gear.

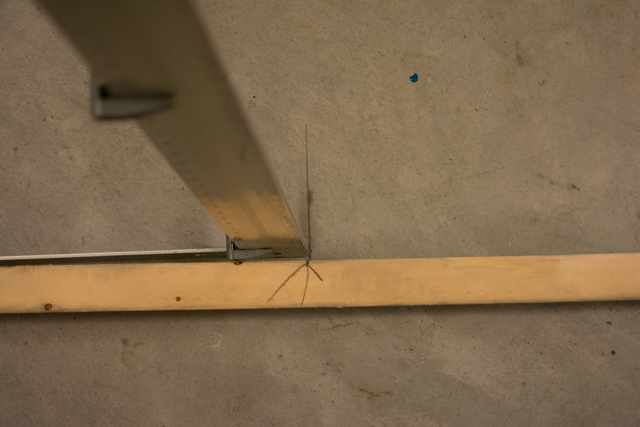

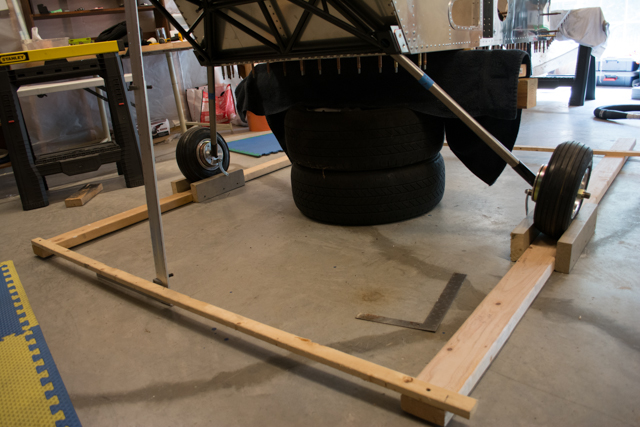

To set the camber of the wheels, I used a method suggested at www.sonexbuilders.com which involved bracing the wheel assemblies using 2×4 lumber, arranged in such a fashion to achieve the 1.7 degree toe-in camber desired, without weight on the landing gear.

I set the fuselage at a height that kept the main landing gear just above the floor (i.e. no weight on the gear.) I used 2 long 2×4’s in order to give me leverage to adjust the camber angle. I used 4 small 2×4’s screwed to the long 2×4’s to brace the wheels. I marked the proper toe angle on my concrete floor. Then I used some 1×2’s to lock in the desired toe-in angle before drilling the holes in the wheel axles. I used spare supplies in my basement (a heavy boxing bag, and some water softener salt) to hold everything in position while I performed the drilling process.

The drilling process was messy to say the least. LOTS of cutting oil was used to keep the bit cutting through the titanium without overheating.

Once the axles were drilled, I fit the gear onto the struts.

And set the plane onto its landing gear for the first time!

One Response to Fuselage Completion #2 (Main Landing Gear Legs)