Total Build Time: 745 hours.

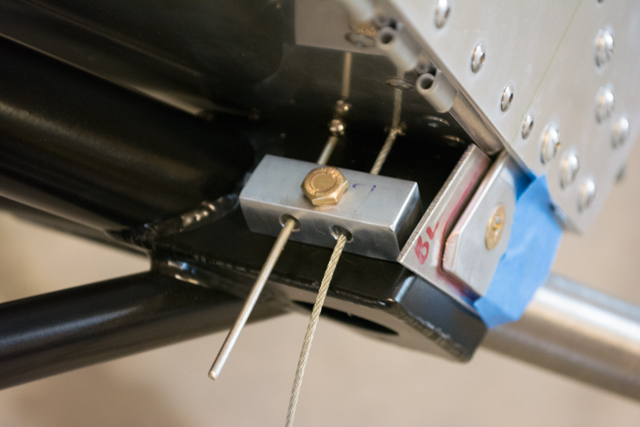

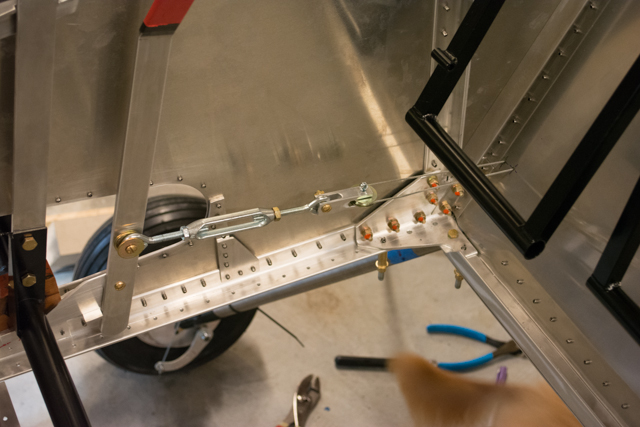

For the brake system I intended to use the system as called for in the plans, with an addition of a turnbuckle to allow for easy brake cable tension adjustments.

Sourcing the parts for the brake system ended up being more of a chore than I’d imagined. There were several parts that I needed to hunt for to find. For example, the brake cable housing I ended up getting at a bicycle shop (I could not find it in any hardware or auto supply stores in my area.)

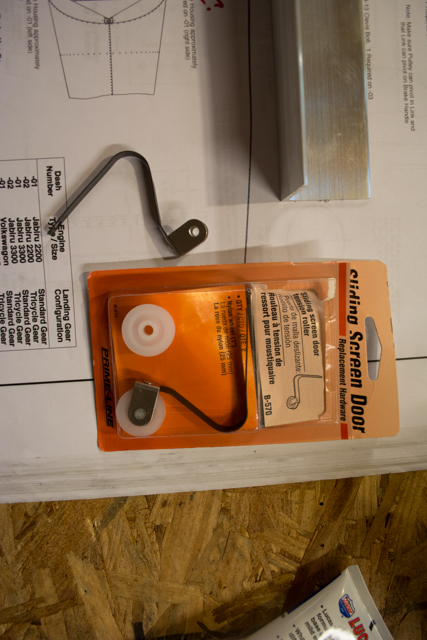

I found the screen door rollers at home depot, and a turnbuckle at ace hardware. I needed a single left-hand threaded nut in order to lock the turnbuckle position, and none of the big box hardware stores carried them. Also worth mentioning that I couldn’t source any left-hand threaded nut smaller than 1/4″, so that’s the size turnbuckle I used.

I’ll note however that even though those nylon rollers seem to fit the description in the plans, they are totally inadequate as they deform too easily.

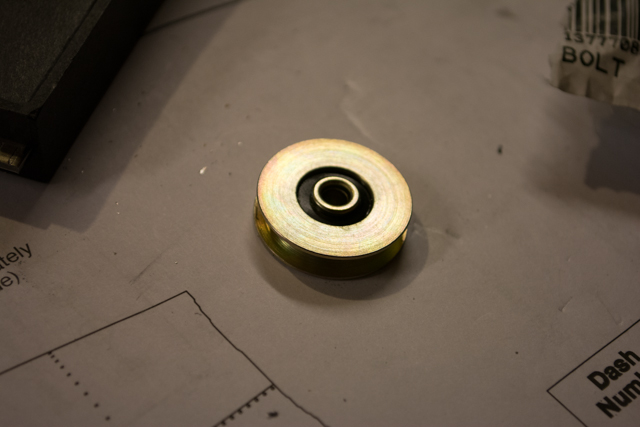

I found some metal rollers to use instead, although they were slightly larger and had a smaller hole than the plans called for. I made some minor modifications to make it fit.

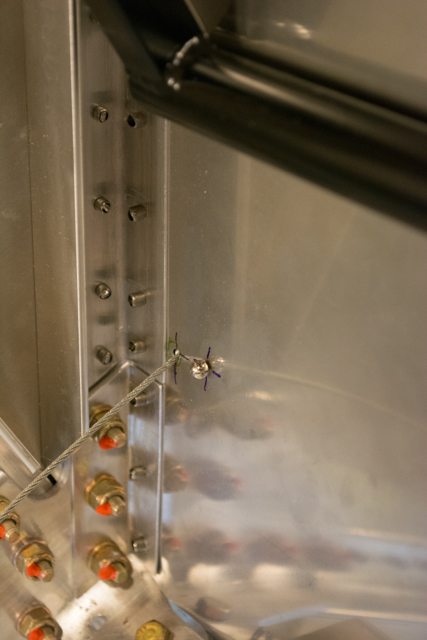

To locate the holes for the brake cables to pass through the firewall, i used 2 magnets.

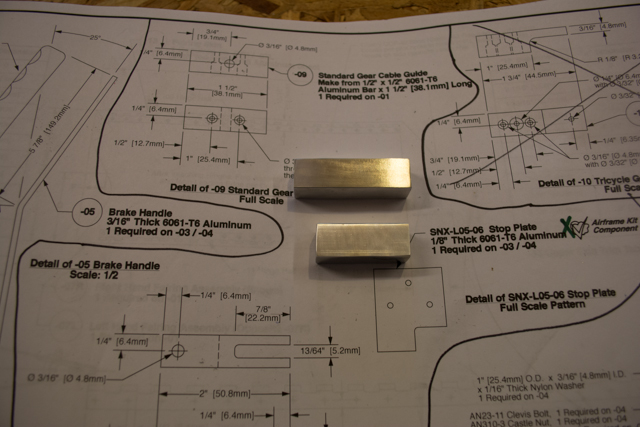

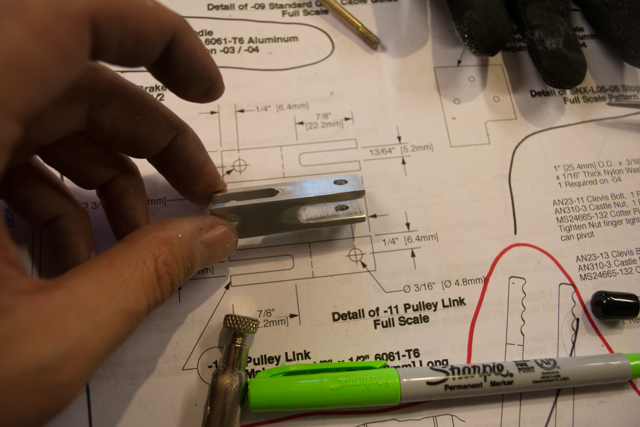

I fabricated the brake handle and associated parts and assembled them.

Finally, here is a picture of the turnbuckle I used to allow for easy tension adjustments.

2 Responses to Fuselage Completion #9 (brake system)