Total Build Time: 1198 Hours

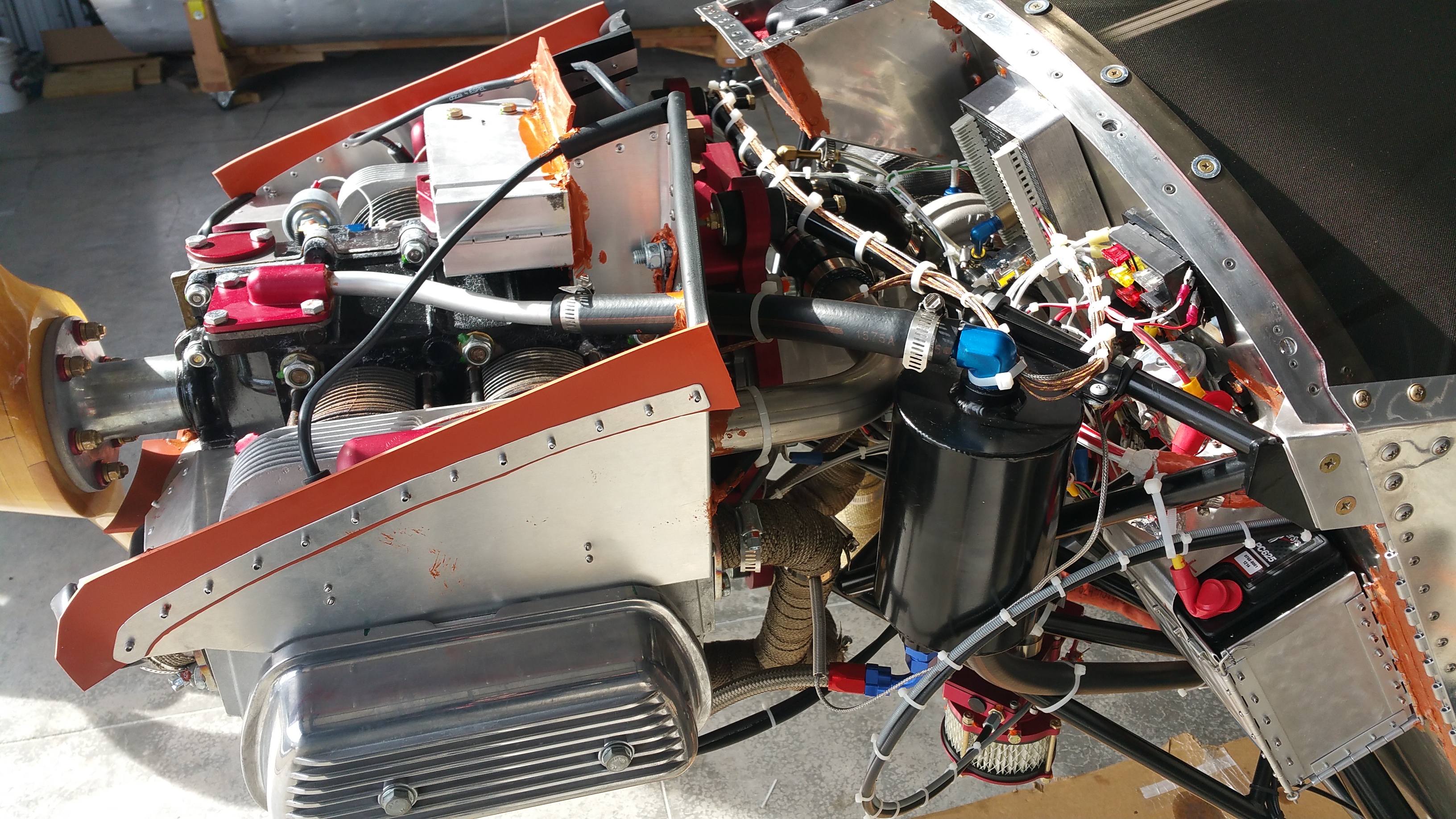

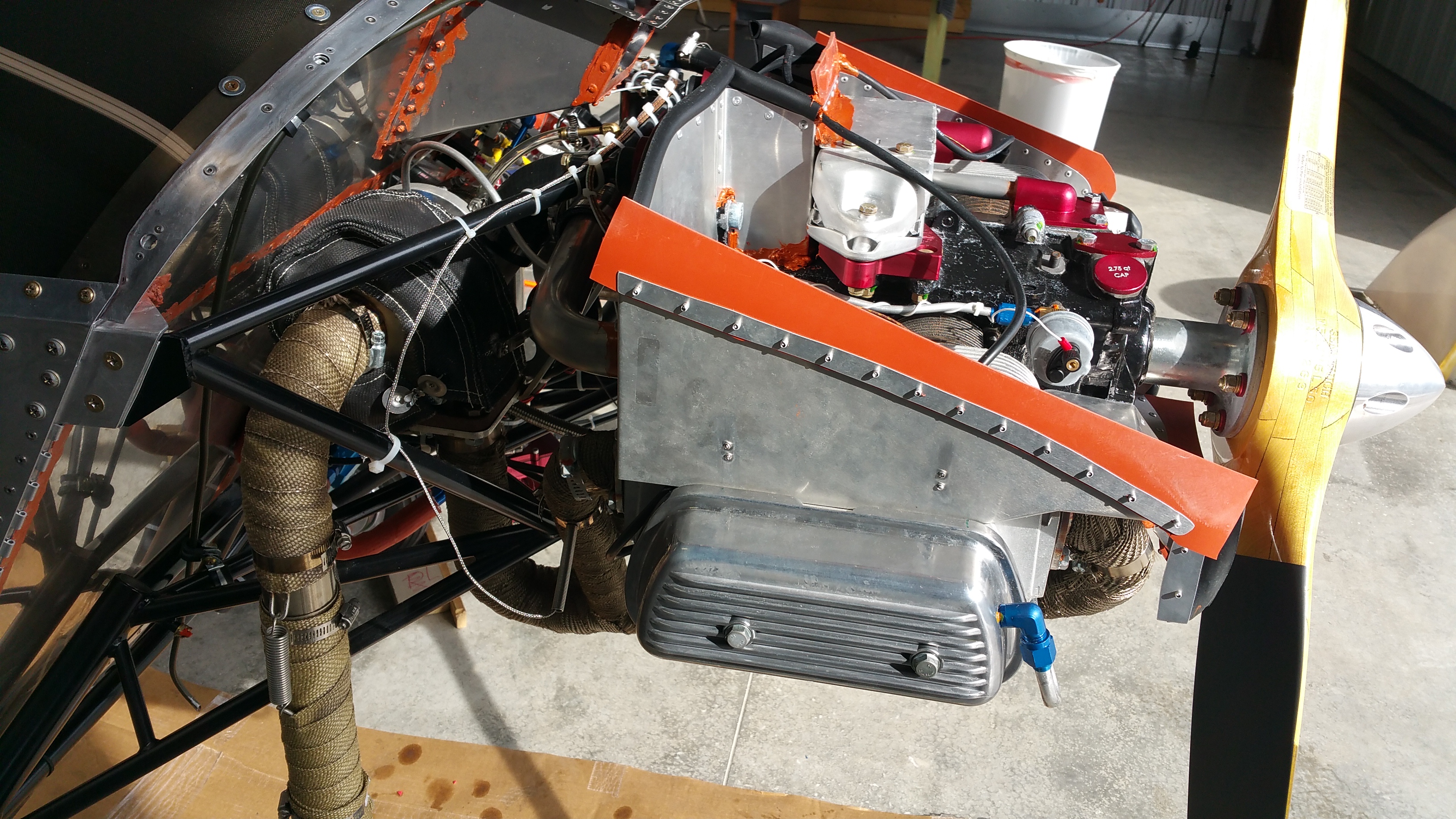

This post details most of the final details and preparations that allow me to say the following: the engine is ready to fly. To summarize, I’ve performed my initial ignition and fuel test runs, made my final cutouts and adjustments to the cowling and baffles, and made some small tweaks to the point that I’m satisfied with my situation forward of the firewall to the point that I think it’s pretty much done. Now for a few details.

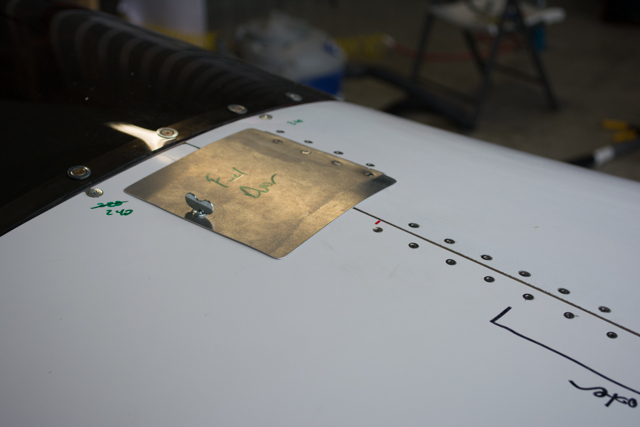

I completed the fitment and attachment of my fuel filler door.

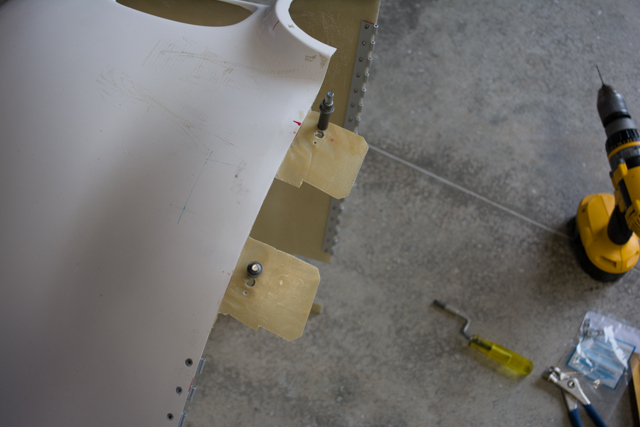

I installed south-co fasteners on my forward two tabs that join the left and right sides of the cowling.

I made the cutout for the exhaust in the cowling.

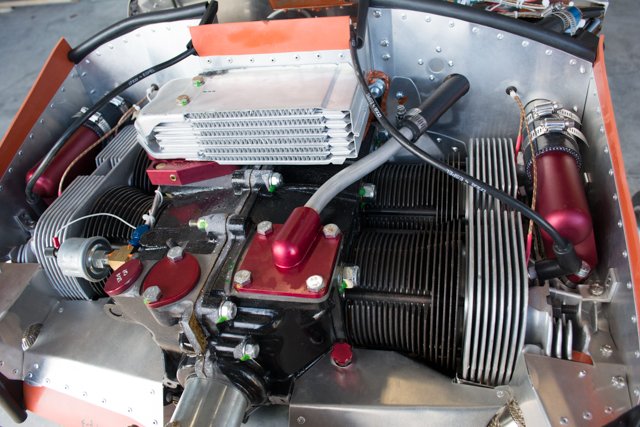

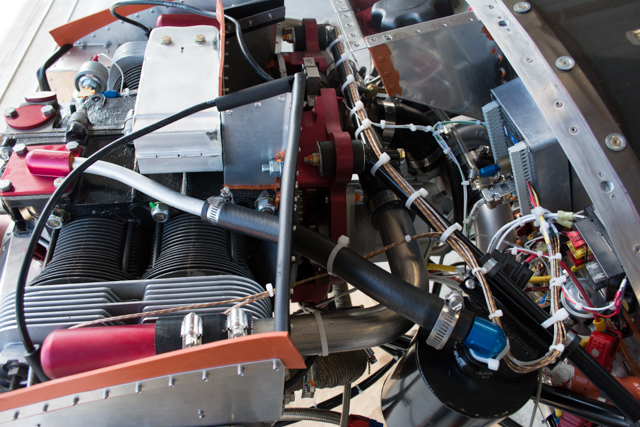

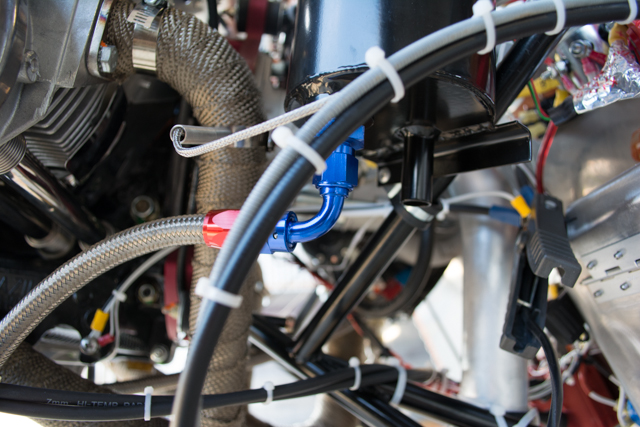

I installed my oil breather tube and oil seperator. The seperator is secured by 3 rubber clamps with bolts through the flanges on the seperator. I had to anneal the oil breather tube using a blowtorch to make it soft enough to put the bends in it. I used an oil-proof hose that was actually fairly difficult to source (found it on Ebay.) It’s easy to find the proper sized car radiator hose, but they’re not rated for oil.

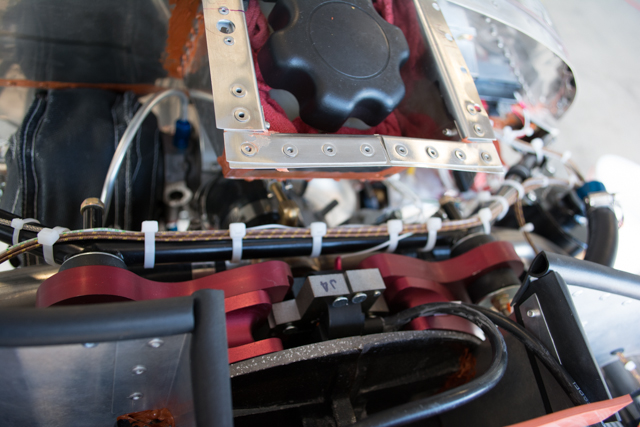

I bundled, secured and connected all my my electrical connections (EGT, Cylinder temp, ignition wires, oil pressure and temperature.)

I filled in all the gaps around the baffles with RTV silicon. Here are some more engine compartment shots that pretty much some up what I currently consider to be my ready-to-fly engine.