Total Build Time: 1296 Hours

After nearly a year hiatus from working on my nearly-finished Waiex (primarily due to the procurement and arrival of a new member to my family!) I returned to the Hangar to start dusting off the project for the final push to completion.

In doing so, I performed an engine test run on my still-never-flown Aerovee Turbo. Remarkably after sitting for several months without being run (I’m never dong that again), it fired right up within a few turns. I warmed it up, and tried a short powered test runup, which at full throttle gave me the following numbers:

~27″ Manifold pressure

~2700-2800 RPM (Sensinech turbo-aerovee climb prop.)

Since I had already read (but not yet performed) the Turbo Service bulletin, I immediately knew where my issue was. After shutdown and cooldown, I removed the intake manifold to the turbo, and felt with my finger that the impeller was very resistant to movement (this procedure is detailed in the SB.) Still, I was able to get it to start turning with my finger, and after about several rotations it suddenly freed up substantially, after which it seemed to spin freely.

I then performed another engine runup and was greeted with 40″+ MAP and 3300+ RPM.

I then performed the service bulletin on the turbo, here are a few photos:

Removed the old oil line connector to the oil pump with the rubber O-ring.

Replaced with the new connector with a crush washer and no O-ring.

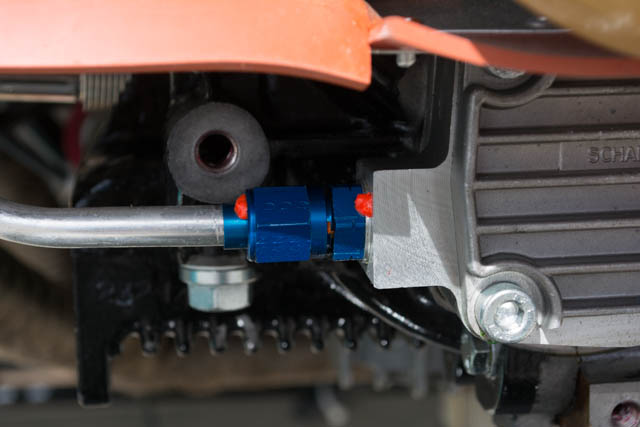

Added an additional external oil filter between the oil pump and the turbo.

Replaced the heat shield blanket on the turbo with a stainless steel heat shield.

Also (not pictured) I re-clocked the oil section of the turbocharger so that the oil drain is vertically perpendicular to the ground when the aircraft is sitting on the ground. I also added the machined drain sump to oil line from the turbo.